COMBINATION DRENCH SHOWER AND EYE-WASH WG7052fY

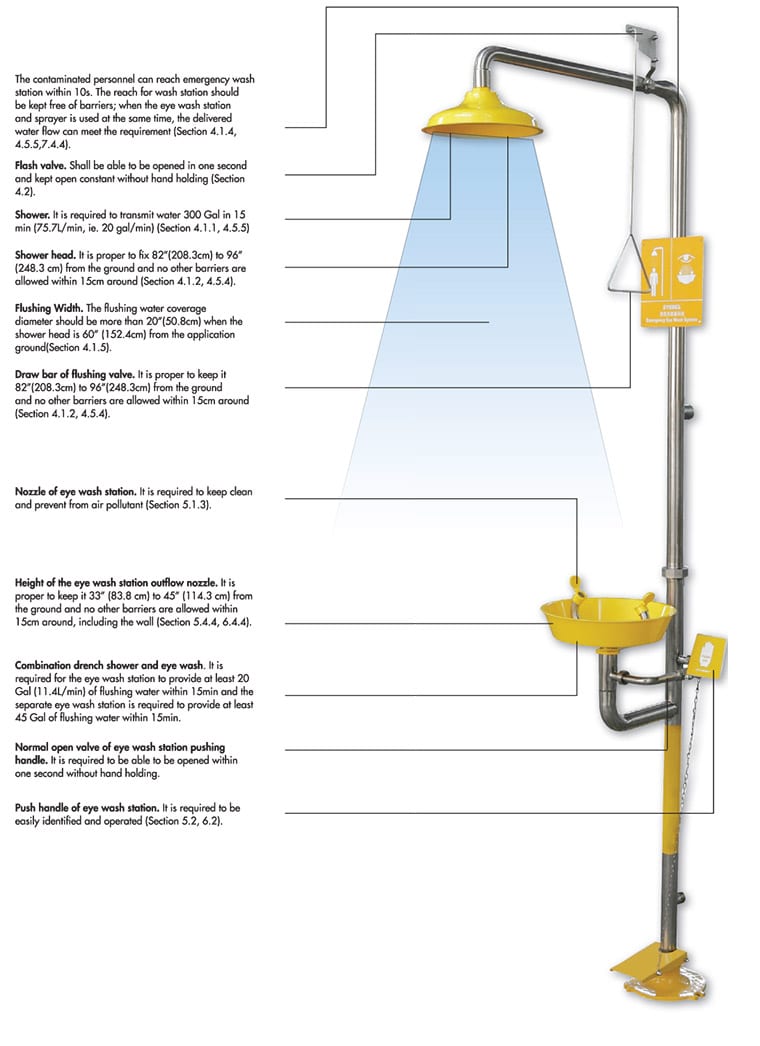

The contaminated personnel can reach emergency wash station within 10s. The reach for wash station should be kept free of barriers; when the eye wash station and sprayer is used at the same time, the delivered water flow can meet the requirement (Section 4.1.4, 4.5.5,7.4.4).

DRENCH SHOWER & EYE WASH CHARACTERISTICS

- Materials: ABS plastic + 304 stainless steel.

- Main pipe fittings adopt stainless steel materialized oil resistance, acid proof, alkali prevention and saline solution performances.

- Push handle and pedal switches are at your option for flexible control of switch and easy operation; the flashing value controlled by the draw bar of the sprayer can be opened in a second and kept open with no need for hand holding.

- Living water supplies.

- It applies for eliminating the harm caused by chemical liquid spraying to body, eyes and face; the sprayer is used to wash away chemical pollutants on face and eyes in emergency.

- It complies with regulations of ANSI/SES on emergency eye wash station and showering equipment – ANSI Z358-2012.

- The inlet of eye wash station he inlet of vertical eye wash station is 1450mm from the ground.

- The outlet of eye wash station is 210mm from the ground.

DRENCH SHOWER & EYE WASH SPECIFICATIONS

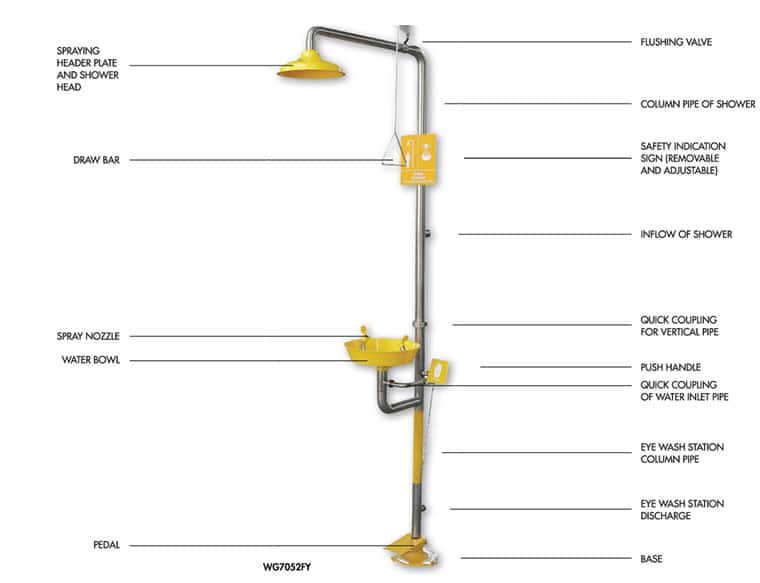

- Main pipe fittings: 304 series of stainless steel.

- Water basin: ABS plastic; draw bar, spraying header, cross bar, vertical.

- Column pipe: baking varnish galvanized steel; base: aluminum casting.

- Shower head: 240mm (9.4) 304 series of stainless steel. The shower head and spraying header are 210cm from the ground.

- Spraying header plate: ABS plastic; dimension: 255x75 (diameter, height/mm).

- Valve: 1 inch female thread, stainless steel, full flow continuous opening ball valve.

- Initiating device: galvanized steel triangular draw bar.

- Spraying header: 1 inch baking varnish galvanized tube.

- Column pipe of sprayer: 1+1/4 inch baking varnish galvanized tube.

- Inflow of sprayer: 1 inch male thread.

- Flow rate of sprayer: up to 75.6L/min under1.4 kgf/cm2 pressure (delivers 300 gallons of water in 15min).

- Eye wash station is equipped with pneumatic spray nozzle and continuous opening ball varnishalve controlled by paddle-type handle.

- Quick coupling: vertical pipe 42mm, water inlet pipe 20mm.

- Water bowl: ABS plastic; dimension: 320x95 (diameter, height/mm).

- Quick coupling: for vertical: pipe the diameter is 42mm, 304 stainless steel; for water inlet pipe, the diameter is 20mm, 304 stainless steel.

- Spray head: 304 series of stainless steel, with dust cover; green ABS plastic eye/face wash nozzle, with self-closing nozzle protection cover, reducing pollution probability. The spraying header is 100cm from the ground.

- Valve: 1/2 inch female thread, stainless steel materials.

- Inlet of eye wash station: 1/2 inch female thread.

- Discharge of eye wash station: 1 inch female thread.

- Flow rate of eye wash station: it is up to 11.4L/min under 2.1 kgf/cm2 pressure (delivers 45 gallons of water in 15min).

- Column pipe of eye wash station: 1+1/4inch baking varnish galvanized tube.

- Weight: 9.5Kg & Package: carton, 30x83x35 (height, length,width/cm).